Sparkling Winemaking: Tirage and RDL Services

BASE WINEMAKING

Traditional method sparkling wine is one of the more complex and technical wines to make. It requires specialist expertise and equipment.

At the Australian Cuvee Centre we offer a complete winemaking service from pressing and fermenting the grapes through to labelling, packing and storage. For quality control and assurance purposes every step of the winemaking process, for every batch of wine, is digitally recorded in Vintrace.

We also cater for those who prefer to complete part of the process in their own facilities including base wine making.

Our facilities are set up to make traditional method sparkling wine. We can also assist in Pét Nat and Ancestral method winemaking and will have Charmat method sparkling online in late 2022.

Pressing and Fermentation

The grapes, which are typically hand picked, are refrigerated overnight before whole bunch pressed in our EHP 5000L Scharfenberger Europress fully open slotted pneumatic airbag press capable of 4.5 tonnes whole bunch pressing. Maximising extraction and multiple press cuts (free run and pressings) provide multiple product options for our clients.

Wines are then barrel fermented and matured in French barriques.

Fining, Blending, Stabilising & Filtration

Fining, chilling, colour stabilisation is all part of our winemaking process.

All wines are cold stabilised and cross flow filtered, using JU.CLA.S isobaric cross flow with filtration rates of up to 3500 L/h, ensuring minimal wine loss in single pass and minimal heat pick up.

Where necessary, we also sterile filter incoming base wines.

Tirage Process

Yeast cultures are created for your individual base wine over 5 days. Yeast counts are conducted to ensure yeast populations are within specified range to ensure a healthy secondary ferment and desired pressure is achieved during tirage.

The base wine is then sweetened and yeast culture is added to the wine in temperature controlled tanks to ensure consistency throughout the tirage process.

Your wine is then bottled on our Bertolaso bottle filler with fully automatic depalletiser capable of filling speeds up to 7500 bottle/hour with 3 head crown sealing unit with automatic air feeder.

Wines are then placed in bins (or cages) and stored in a temperature controlled warm room for up to 8 weeks until secondary fermentation is complete. Once the wine has reached desired pressure the wine is then transferred to temperature controlled warehouse for long term storage in cool and constant temperature. You choose the length of stay for tirage (from 9 months to over 3 years).

REMUAGE, DISGORGE AND LIQUEUR (RDL)

We work you to deliver sparkling wines to you in time to meet your sales targets and customer demands. Starting from release date we will create a production schedule that meets your needs.

Automated remuage (riddling) is done using gyro-palettes that process 500 bottles in a single cage, and rotate every 15 minutes 24 hours a day. This process continues for 7 days. On completion of remuage, the bottles are neck-down (‘sur pointes’) with the yeast lees sediment sitting in the neck of the bottle, ready for disgorgement.

We can also do manual riddling for small batches, magnums and unusual bottles, if required.

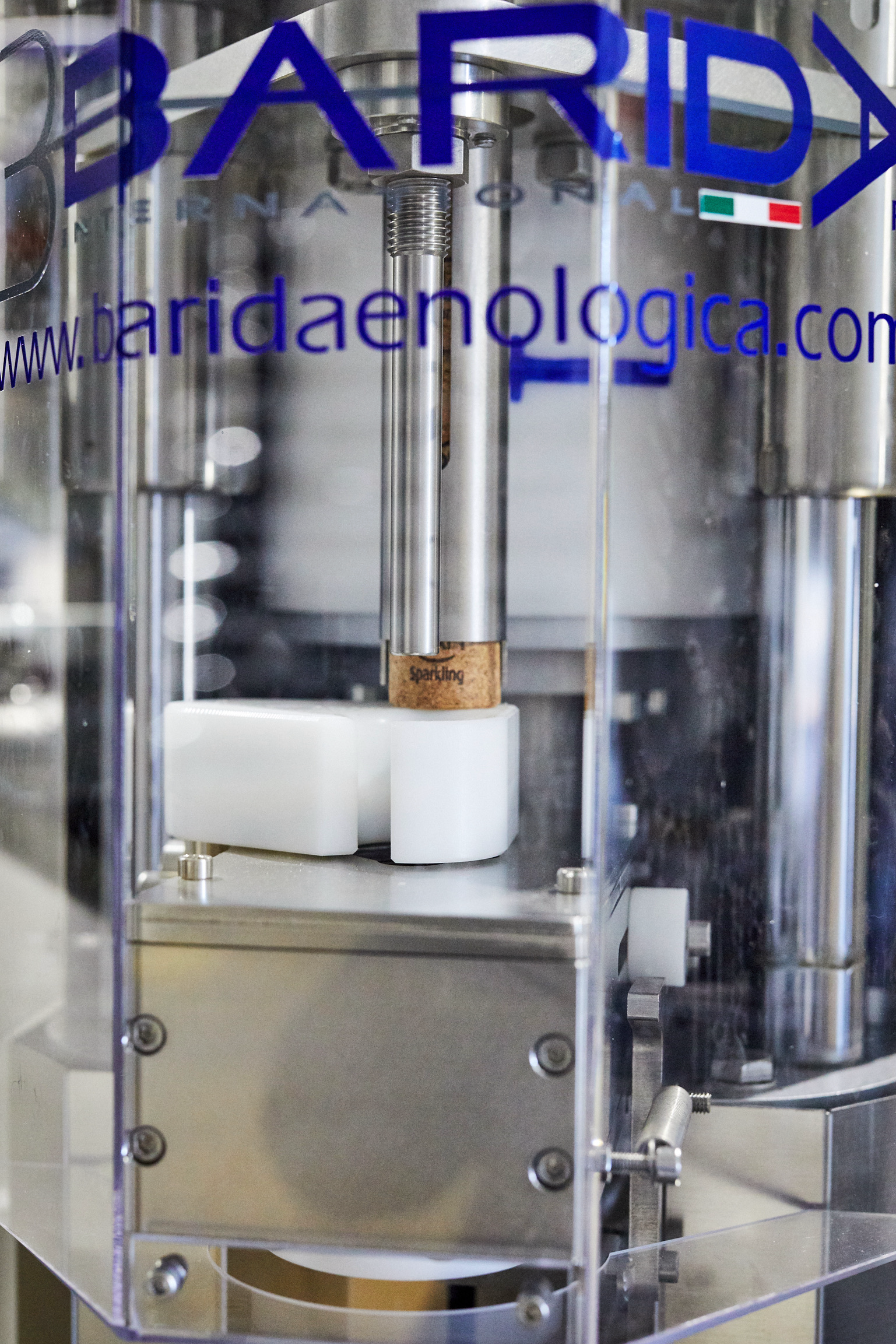

Bottles are then cooled to ideal temperature prior to disgorgement to minimise gushing and product loss. Wines are disgorged using Champegel linear neck freezer for large runs (capable of 2100 bottle per hour) and Champegel rotary 56 bottle neck freezer for small batches.

We can customise the dosage to your specifications. We host on-site dosage trials with clients to get the exact sweetness profile you seek, and offer custom liqueur suggestions to enhance the taste profile of your wines.

We also offer transfer to large format bottles up 22L.

FLEXIBILITY TO SUIT YOU

You choose how little or how much you want to be involved. Our highly knowledgeable winemakers guide you through the sparkling process. We are available to you, through every aspect of production.

Clients are encouraged to visit throughout the winemaking process, or watch tirage bottling or disgorging take place. Come down and see your sparkling wine being processed. Taste and check your stock at anytime - giving you better access and control to your premium product.

SPARKLING CONSULTATION

Our approach is not a one size fits all. Work with our chief winemaker on your sparkling wine development from start to finish.

Develop a plan for all your sparkling wine styles, Vintage or Non Vintage, Roses, Blanc de Blancs and more. From harvesting choices through to base wine production, maximising juice yield and creating unique styles. Establish ideal tirage ages, maturation policies and liqueur choices, all geared to your own winemaking and brand philosophies.